History

2016 - Positioning for growth

New England Airfoil Products Inc., is positioning itself to support the life cycle of gas turbines; development, maturity and legacy supply.

The scale of the facility and its long established manufacturing process capability and capacity enables the company to be suited to both high and low volume production.

Strong and effective supply chain management support the major OEMs needs for reliable and vertically integrated engine ready product supply.

Capability acquisition will continue such that New England Airfoil Products, Inc. will enter into the next decades fully equipped to support the latest manufacturing technologies demanded by world's leading OEMs.

1973 - 2015 - Capacity & Capability acquisitions

The company strategy was to continually expand both capability and capacity to service its ever increasing customer requirements. The wide range of customers and markets addressed demanded that the company's capabilities to include both hot and cold section products.

The engine programmes supported by the company included the following high profile civil and defence propulsion units; PW F4U, USAF XS-2, PW4000, Honeywell T53 & T55, Honeywell ALF502, PW JT8, PW J52, R-R 570, PW F100, PW 2037, AGT 1500, GE F404, PW JT11, PW JT3, PW TF33, PW3005, PW TF30 and GE90.

1972 - TRANSITIONS TO HIGH VOLUME PRODUCTION CAPABILITIES

The company strategy was to continue the development of blades and stator vanes on emerging engines and capture the high volume production requirements.

This success was also tied to the development of their ingenious ECM machines; which produced concave, convex, platform airfoil surface in a single operation.

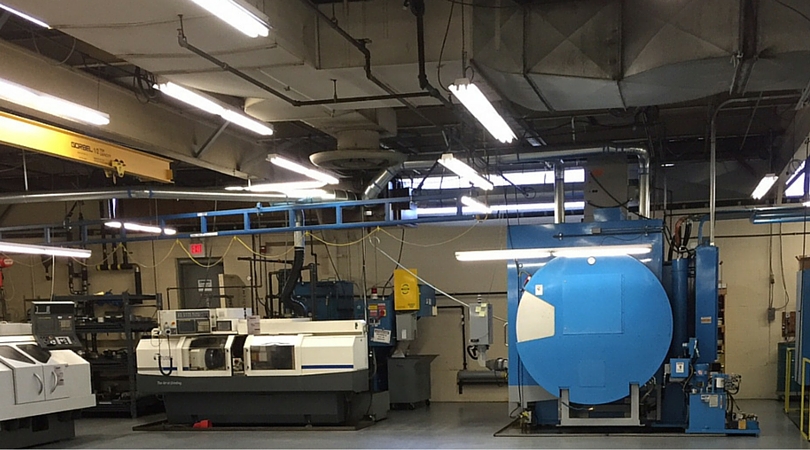

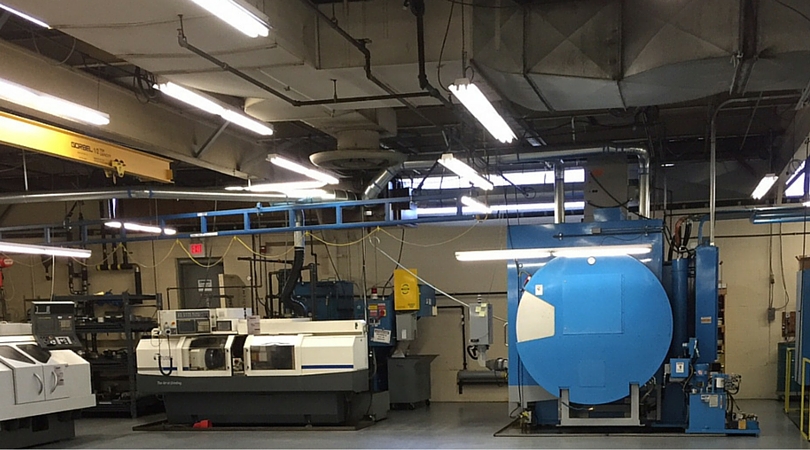

(pictured is the EDM/ECM area of the company that produced 1000's of airfoils per month.)

1963 - Current Facility Inauguration

The site at 36 Spring Lane, Farmington, CT was first built on a footprint much smaller than we see today. The plant has been significantly expanded over the years to accommodate the greater capacity that was needed throughout the various stages of growth.

The first Electro Chemical Milling of airfoils was introduced into the facility the same year. This process, in its crudest form was invented by Michael Faraday in the early 1800's, though in 1963, its use for airfoil machining was considered "cutting edge".

1955- NEW ENGLAND AIRCRAFT PRODUCTS FOUNDED

George Einstein, Albert Einstein’s nephew, founded the company in 1955, George was a brilliant engineer, clearly possessing some of his uncle's DNA.

Recognizing the surging demand for engine ready compressor airfoils, George focused his career on developing specialized blades and components for turbines and aircrafts.

The company rapidly grew from a small "shop" outfitted with World War II surplus equipment into a thriving international business.

Over the years, the facility has furnished products for the most demanding and successful OEMs in the marketplace including: Pratt & Whitney, Westinghouse, GE, NASA, Rolls-Royce and Hamilton Standard.

The Convair F102 Delta Dagger aircraft (pictured) was one of the aircrafts supported in its development by the company.

1940's - NEW ENGLAND MACHINE & TOOLS FOUNDED

Founded by Mr. George Einstein and Mr. Paul Campbell.

The company was formed to specialize in the Design and Manufacture of airfoil forming machines. This company set the seed for the formation of New England Aircraft Products, the company we now call New England Airfoil Products.

Pictured is an example of P&W r-2800 Double Wasp Radial engine which was found on airframes such as F4U Corsair, F-6F Hellcat, P-47 Thunderbolt, DC-8, C-69 the company provided many compenents for use in building this multi use engine.